The Homebuilt Submarine

By Ron Wanttaja (ron@wanttaja.com)

This is a photo of me with the sub, taken around spring

1976.

Everything painted orange or yellow is part of the sub (with

the

exception

of the fireplug in the foreground, of course :-). The

yellow box

contains the battery, the skids are 4x4s, the trusswork is

welded steel

tube, and one of the white trolling motors used for propulsion

can be

seen

next to the black-painted aft stabilizer. The long

tube

running

horizontally just under the hull connected the joysticks in

the two

cockpits.

The "Notch" on top of the hull between the cockpits carried

the scuba

tank

used for blowing the ballast tanks. The forward dive

plane can be

seen (edge-on) in front of my right hand.

Before I start this story, I should mention that the title isn't

a

play

on words. This isn't a tale about a float-equipped homebuilt that

takes

the "Z minus 1000" route.

It's the story how, for one summer, I was the skipper of the only

submarine

in North Dakota.

I realize the subject matter is a bit of a reach for

rec.aviation.homebuilt.

There's a lot of aviation in this story...and a few lessons, I

hope,

for

the airplane builders in this forum. This is the story of two

pilots

who

literally get out of their depth...trying to base the design of a

submarine

using only their knowledge of aeronautics.

The story starts over twenty years ago, in a Civil Air Patrol

cadet

squadron in Fargo, North Dakota. Our commander, who I'll refer to

as

the

Major, made life in the squadron...umm, "interesting." We were the

top

squadron in the wing, a position we held for the last five years I

was

with the unit.

The squadron stayed on top by offering a wide variety of unusual

activities...only

a few which had anything directly to do with the mission of Civil

Air

Patrol.

These activities tracked the interests of the Major. The Major

gets

interested

in target shooting...and the squadron soon has an NRA-affiliated

rifle

team. The Major wants to learn to scuba dive...and the squadron

soon is

taking lessons at the YMCA. The Major wants to learn martial

arts...and

soon we've got a karate instructor teaching us how to break boards

(ouch!).

The Major wants to water ski...and the squadron soon has an

18-foot

speedboat

with a big herking motor.

It wasn't as selfish as it sounds. The Major was a born salesman;

the

kind of guy who can talk anyone out of anything. When equipment or

instructors

were necessary, he either talked the owner into a donation or paid

for

it himself. For the rifle team, for instance, he discovered a

little-known

civilian marksmanship program run by the US Army, and was able to

get

free

ammunition and rifles. He got his fun...but the whole squadron,

forty

kids,

got to join in as well.

The submarine grew out of the Scuba phase, of course. We had

about

fifteen

cadets take the course. The Major wasn't especially physically

fit, and

having a batch of youngsters outswimming him was hard on his ego.

He

found

the plans for a hand-held Scuba tow in Popular Mechanics. He built

a

pair

of them and it apparently got his mind working on higher things.

Otherwise, I don't know quite how he got the urge to build a

submarine.

Inspiration probably struck when he stopped by the local Air

National

Guard

squadron on one his occasional "What do you have that I can talk

you

out

of" visits.

The Major struck pay dirt. The next time I visited his home, I

found

him cutting a pair of cockpits into a T-33 tip tank. The Sea Wasp

project

was underway.

The basic concept was a tandem open-cockpit two-seater, where the

occupants

would wear full scuba gear. Two electric trolling motors were

installed

in the rear. Switches installed in the exterior of the tank in

front of

the forward cockpit ran the motors individually forward and back.

Waterproofing

came from tube after tube of silicon RTV.

The tip tank included baffles in the extreme front and rear.

These

became

the sub's ballast tanks. A set of valves (with garden-hose

handles) in

the "instrument panel" sent compressed air into or allowed air out

either

tank. Compressed air was provided by a small Scuba tank located

between

the two cockpits, using the first stage of a two-stage Scuba

regulator

to limit pressure to 150 PSI. There was an indentation in the jet

fuel

tank where the wing stuck in; this indentation provided a perfect

cradle

for the Scuba tank. The cockpit were cut so this notch would be on

top.

The tank sat between the two cockpits.

The tip-tank was mounted atop a cradle of steel tubes, with a

pair

of

4x4 wood skids at the bottom. Skid installation was similar to the

way

a pair of floats are installed on aircraft. The tank itself sat

about

three

feet above the ground. On the cross-braces on the bottom rested a

fiberglassed

wooden box holding the 12-volt bus battery that powered the

motors. The

low position of the battery ensured that the center of lift

(buoyancy)

was always above the CG.

The Major wanted to "fly" the sub like he did the CAP Arrow, so

the

cockpits got dead-stock joysticks. Instead of using conventional

controls,

though, he came up with a dead-simple system. The joystick in the

forward

cockpit ran out the bottom of the fuselage, where a flat

plexiglass

vane

was installed. The joystick was pivoted a foot or so above the

vane.

When

the stick was tilted back, the vane tilted as well. Move the stick

to

the

side, and the vane tilted. There was no linkages...the vane merely

mounted

directly to the bottom of the joystick tube.

The Major managed to get just about everything donated...the tip

tank,

the motors, and the battery. He eventually talked a local auto

shop

into

painting the thing...bright orange, yellow trim, with "Sea Wasp I"

painted

below the front cockpit and a big CAP decal on the nose.

As you might expect, a T-33 tip tank, two electric motors, and

lead-acid

bus battery makes a pretty heavy load. The Sea Wasp's draft was

about

four

feet, which leaves out using ordinary boat ramps.

That's where having a CAP squadron comes in. By organizing scuba

weekends,

the Major could be assured of ten to twenty husky farm-country

teenagers

to haul the thing into and out of the water.

Anyway, the Sea Wasp was ready for its water trials. One drawback

of

North Dakota, of course, is the scarcity of open

water...especially

deeper

water. Fargo, though, is right on the border with Minnesota (the

"Land

of 10,000 Lakes," if you believe the license plates). Many people

in

Eastern

North Dakota own small lake cottages, and the Major talked someone

into

the use of a rather nice place.

Which brought up one weird bit of trivia: Although it was a North

Dakota

sub, the Sea Wasp never made a dive in its home state....

When taken into the water, one problem immediately arose. Or, to

be

more specific, DIDN'T arise: The Sea Wasp didn't have enough

buoyancy.

Released, it sank, even with the ballast tanks blown dry.

The Major was ready for that. He had brought sheets of styrofoam.

These

were cut out, curved, and glued to the inside of the hull.

With that, the Sea Wasp could be dived and surfaced. The motors

drove

it fairly fast, fast enough that the occupant's face masks would

get

ripped

off if they turned their heads to the side.

Unfortunately, it couldn't be controlled worth a durn. The

Major's

steering

vane had very little effect.

I watched a good example. I watched the sub skimming along on a

slow

descent. It approached a rise in the muddy bottom. The vane tilted

back,

with negligible results. The lower skids hit the rise. The front

dipped,

the stern rose. The occupants windmilled their arms in slow

motion,

trying

to keep themselves from floating free of their cockpits while a

huge

muddy

"smoke cloud" slowly expanded from the crash site.

A later test run yielded another big surprise. The Major had the

sub

in deeper water. He descended to about 35 feet.

Then a huge cloud of bubbles erupted from the cockpits, and the

sub

dived for the bottom. Both occupants bailed out.

What had happened? Well, remember the styrofoam the Major added?

It

had collapsed under the water pressure, forcing out all the

trapped

air.

They swam down, tied a rope to one of the struts, and hauled the

sub

ashore. The Major fixed the buoyancy problem and took the sub to

the

lakes

a couple of times for more tests. But by the end of the summer,

he'd

managed

to get the ski boat donated to the squadron and his attention was

drawn

away from the troublesome sub.

I'd been watching the events, and had my own ideas on how to fix

the

controls. I got permission to take over the submarine project.

I knew the control vane had to go. I replaced it with a pair of

large

dive planes mounted just forward of the cockpit...a canard, in

other

words.

A steel tube running crosswise, with the planes themselves being

pieces

of plexiglass about 3 feet long and 2 feet in chord. I mounted the

planes

at about the 33% point of the chord.

How did I pick the 33% point? It looked cool. It's not like I

knew

what

I was doing. It's tough to find submarine design assistance in

North

Dakota.

The linkages to the control stick consisted of a simple pushrod

connected

from the stick to a bellcrank on the canard's tube. Too simple and

too

light, as I soon found out.

Testing had shown the low CG gave the sub scads of roll

stability,

so

I didn't worry about ailerons. The Major said the motor controls

were

sufficient

for yaw...conventional DPDT switches had been entombed in RTV, and

going

forward on one motor and astern on the other gave a reasonable

turn

radius.

Finally, I added a pair of horizontal stabilizers. These were

attached

to the support rods for the motors, and were about two feet long

and a

foot wide.

Time to try it. It was my last summer in North Dakota; I had to

fit

a lake trip in between summer school and work.

One of the cadets volunteered to be my backseater. Fitz had two

primary

qualifications: He was sixteen, and hence believed himself

immortal,

and

he was a cadet second lieutenant, and hence expendable.

Fitz's prior claim to fame was the Three-Mile Moon. On a CAP

field

trip,

we'd had two buses. Fitz had ridden on the front bus, driven by

the

Major.

I rode the second bus, driven by our Wing's Air Force Liaison

Officer,

a crusty old Lieutenant Colonel whose past assignments included

flying

unmarked AT-28s in Southeast Asia. The front bus had been

extensively

modified

by the Major, and unfortunately included a large table just

forward of

the rear window, with a curtain across the bus unfortunately just

forward

of that.

I'd been chatting with the LO as we traveled along a quiet

highway,

when *it* appeared in the back window of the Squadron bus. Fitz's

stern,

to be exact, shining pinkly behind the dirty glass. He'd eased the

curtain

closed so the Major couldn't see him in the mirror, laid down on

the

table,

and dropped trou.

It was an interesting performance. Fitz didn't believe in static

displays.

The full moon rose, set, crawled left, oozed right, bobbed and

shook.

We

in the second bus roared as the show went on for minutes.

The Major *knew* something was going on, from the stifled laugher

from

Fitz's friends behind the curtain. No one answered his roars for

information,

and he eventually stopped the bus. This process took a finite

amount of

time, of course...enough for Fitz to resume an innocent seat and

expression

by the time the Major stormed through the curtain. The Major

stomped

back

to

our bus to ask us what had been going on.

"Ummm," I said. I was still a cadet myself at that time, and

didn't

want to turn Fitz in.

"Hell, Dave," said the LO. "All I saw was a fat old man with a

cee-gar."

The Major didn't think to take "prints" from the inside of the

window.

It would have made for an interesting lineup.

Anyway, Fitz escaped punishment, but the Major never invited him

to

ride the back seat of the sub. He got his chance with me.

So with Fitz in the rear seat of the Sea Wasp, I motored the sub

toward

deep water. The sub was uncomfortable to ride in. The cockpits

were set

up for sitting at nearly a right-angle, which is really only

comfortable

when in full gravity. In the water, as in space, one's body wants

to

assume

a "dead-man's float" attitude. That, combined with the resistance

to

bending

of the wet suits we had to wear, made it hard to stay on the seat.

One's

hips kept floating upward, and one had to use the "sit-up" muscles

continually

to kept an erect attitude.

Plus, of course, the wet suits gave our bodies positive buoyancy.

We

wore our usual diving weight belts, which gave our bodies neutral

buoyancy.

Heavier belts would have kept us in the seat better, but our legs

would

have still kept trying to float up.

Far enough from the shore, I shut the motors down. "Get on your

air,

Fitz," I warned my backseater. I turned the valves to let the air

out

of

the fore and aft ballast tanks. Water closed over my head, and I

flipped

both motor switches forward.

The Sea Wasp moved out. I shoved the stick forward to dive

further...and

the pushrod buckled. I'd hinged the thing at about the 1/3rd chord

point

by eyeball. With the water pressure, there still wasn't enough

balance

to relieve the pressure and allow my (admittedly flimsy) control

system

to work.

I switched to the manual backup mode...I reached out of the

cockpit

with my right hand and grabbed the trailing edge of the canard.

Try

THAT

in your Long-EZ.

I held it steady, as we seemed to be moving along a few feet

below

the

surface. The dappled bright surface flickered overhead, and the

current

fluttered on my face and mask.

I zipped along for a minute or so, then blew the ballast tanks

and

shoved

down on the trailing edge. We bobbed to the surface.

I dropped my scuba mouthpiece. "How was that, Fitz?"

He spat out his own mouthpiece. "How was what? The back end

stayed

up,

I didn't go under."

Hmmm. The sub had tilted enough to put me under, but the stern

apparently

kept its bubble and left Fitz on the surface.

Try it again. Open the vents and *leave* them open. We dropped. I

lifted

the trailing edge of the canard, and the nose dropped. Speed

increased.

It got darker. The nose continued to pitch down. I shoved down on

the

canard's

trailing edge. No effect.

I reached into the cockpit and shot compressed air to both the

fore

and aft ballast tanks...and discovered the Sea Wasp's worst design

flaw.

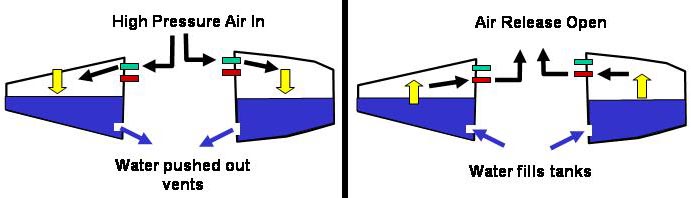

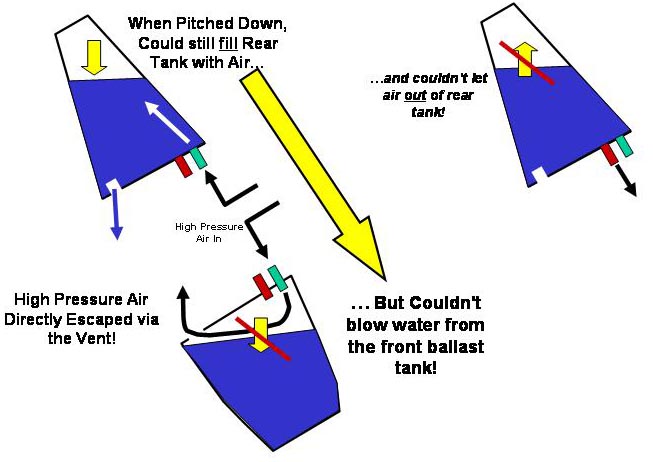

You see, the ballast tanks were vented wrong. The tanks were

built

into

the extreme ends of the converted tip tank. That gave them an

approximately

triangular cross section. Here's the general configuration of the

fore

and aft ballast tanks.

Anyway, the compressed air and cockpit-controlled venting for the

tank

led in at the top of each tank. There was a hole in the tank down

low",

this is where water exited the tank when air was blown into the tank

and entered when the tank vents were open.

Now, take the above drawing and tilt it 45 degrees clockwise.

Note

that

the tank opening effectively *rises* above most of the rest of the

tank.

When I tried to blow the forward tank with the nose down, the

water

would

get shoved out of the tank until the air reached the hole at

"B"... and

it couldn't empty any more because the air would escape out the

hole.

And

in the stern, the same problem existed in reverse... when trying

to

vent

from the top hole, the water line would rise to the vent position,

and

a big bubble would be trapped in the back.

I realized there was a problem early, since forward tank's hole

was

at the bottom of the ballast tank inside the cockpit, and I could

see

the

air bubbling out of the lower hole. I even put my foot over the

hole,

trying

to stop it.

To no avail. We kept going down. I threw both motor switches in

reverse.

With a surprisingly gentle thud, we hit the bottom. The stern

dropped

to the level position, and suddenly the tanks worked properly. The

compressed

air purged the water from the forward tank. The air bubble started

to

leave

the stern tank. But of course, since the front tank was being

purged

using

150 PSI air, it emptied out much quicker.

The nose started to rise. I turned off the air to the forward

tank

and

opened the vent.

Too late. We pitched up and headed for the surface, in a reverse

of

our plunge downward. We broached like the Seaview on chili night.

Alarmed by the lack of control, I shot air into both tanks to

hold

us

on the surface.

"Hey, sir," called Fitz. "We got down to fifty feet." Fitz, with

no

controls and no way of asking me what was going on, had stuck with

me

the

whole way.

Why we didn't both get embolisms and gawd knows what else, I'll

never

know. I'd had enough of trying to run that bucking bronco for a

day...besides,

with all the frantic vent blowing, I didn't know how much air I

had

left

in the sub's tank. Back to shore for considerable head-scratching.

We

didn't

have a spare small tank for the sub, so that was it for U-boating

that

weekend.

I took it out once or twice more that summer. By submerging

carefully,

slowly filling or venting both tanks, I could keep the thing

level.

The trouble is, the canard didn't really work, either. The Major

and

I had both wanted an underwater "airplane". We weren't even close.

The summer ended with the Sea Wasp's problems still unsolved. I

graduated

from college that fall and entered the Air Force. The Sea Wasp sat

abandoned

under a tarp in the Major's yard.

If I'd had another winter to mull over the problem, I might have

come

up with a solution. Over the years, I've done a bit of thinking

about

how

we might have achieved our goal.

The Major and I, in our goal to develop an underwater airplane,

had

forgot one major design attribute of airplanes: Wings.

I'd neared the solution with my addition of the small horizontal

stabilizers.

The canard didn't work, though, because pitching the sub up or

down

didn't

increase or decrease the "lift" of the vehicle.

Take the sub moving along at 5 MPH. The canard commands nose-up.

The

thrust vector changes, giving a slight effect in the desired

direction.

But the only change in lift was the impact lift of the relative

"water"

against the rather narrow, round, belly of the tank.

If we'd had a pair of short, narrow-chord wings on the sides of

the

sub, I think we would have gained a lot of maneuverability. We

needed

some

flat-plate area; a shape like a Stingray instead of a torpedo.

Alternatively, we could have gone with a more sub-like route by

adding

aft dive planes to go along with the forward ones. A set of large

planes

would have allowed us to change our depth without major changes in

attitude.

Either way, the ballast tank system would have had to change.

Adding

a ballast tank at the CG of the sub would have been the best

overall

solution,

eliminating the odd trim effects of the tanks in the extreme ends

of

the

sub. A center ballast tank would have been simple to add, although

it

might

have cramped the rear-seater's leg room.

Finally, speaking of leg room, the personnel accommodations could

have

been improved to allow more comfortable seating. Seat belts would

have

locked our bodies into the proper positions; however, I would have

had

a lot of misgivings over essentially tying myself into the

vehicle. It

was fun to play with, and we could ignore the danger by

rationalizing

that

"ejecting" was easy...just a spring of the legs and we'd float

away.

Still, it's probably fortunate that the Sea Wasp was abandoned

after

just two summers. Fitz and I were lucky to have avoided problems

in our

uncontrolled plummet and rise. About the only thing in our favor

is

that

we spend next to no time at the lower depths, thus avoiding the

bends.

We didn't know what we were doing; a situation fraught with danger

in

both

Scuba diving AND aviation.

But at the time...geeze, it was fun....

Return

to Sea and Sky Aviation Page

Return

to Sea and Sky Aviation Page